Description

MEFIAG® Filter System All Polypropylene Construction

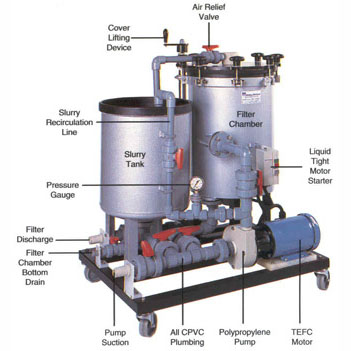

Series 0310-PP is a design that incorporates the best that MEFIAG has to offer including all polypropylene construction and magnetic drive pump as standard.

Features and Benefits

- All polypropylene construction withstands

highly acidic environments - Magnetic drive pump with silicone carbide

bearings is standard - “Unitized Pack/Cover” disc assembly

- Large sludge holding capacity

- Low disposal cost

(100 GPH per sq/ft of surface area) - High efficiency

- Pre-coated flow rate to 1600 GPH

- Temperatures to 180°F(82°C)

- Specific gravities to 1.5

- Shipped ready for immediate operation

Precoated Flow Rate (Filtering Capacity): 600 GPH

Open Pumping Capacity: 2,400 GPH

Filtration Surface Area (Square Feet) 7

Number of Filter Media (8-1/8″” Diameter) 20

Sludge Holding Capacity (cubic inches) 123

Approx. Dimensions: 31″” Lonf x 16″” wide x 36″” high

Approx. (Crated) Net Weight (Lbs) 225

Hose Connections (Suction and Discharge): Suction: 1-1/2″” , Discharge: 1-1/4″”

Hose Length: (2) 10′ long

Motor: 1 HP TEFC

Filter Pack Easily Maintained

All filter discs are attached to the ‘ALL PRO’ Series filter cover to allow easy removal for maintenance. The unique cover design on all models converts into a filter pack stand when the pack is removed. Both disposable and reusable filter media can be utilized.

Filter

The filter chamber is constructed of all polypropylene with bottom inlet and top discharge.

Stainless steel eyebolts with handwheels hold the powder coated steel cover in place. An air release diaphragm valve is provided.

A stainless steel pressure gauge (0-60 PSI) is supplied with a corrosion

resistant guard.

Base is polypropylene with stainless steel channel support structure and polypropylene feet. Casters are available upon request.

Unitized Pack

The disc assembly is all polypropylene. All filters discs are attached to the filter cover to allow easy removal for maintenance. The unique filter cover design on all models converts into a filter pack stand when pack is removed.

Filter media selected for the application is placed between the rigid polypropylene discs. Ten (10) micron cellulose is standard. Carbon/cellulose (10 micron) and polypropylene of various densities are available.

Magnetic Drive Pump

A polypropylene, magnetic drive pump Model PM is furnished with a 1HP TEFC motor. High purity silicon carbide bearings and viton orings are standard. The magnetic switch motor starter is housed in a liquid tight enclosure.

Slurry Tank – (Option)

The slurry tank is all polypropylene construction and is furnished with Model PP-SY units. Slurry tanks are used to facilitate pre-coating, addition of carbon (if required), and solution makeup. These are sized to store the complete capacity of the filter

chamber during changing of the media or maintenance.

Piping, Valves and Connections

Piping, valves, and connections are all hard pipe polypropylene. SY models are piped to allow for flow from the solution tank, slurry tank, and the filter chamber.

Option – Contact Us

-Granular carbon treatment kits

-Cartridge kits

Click Here To Download:

0310 Product Bulletin.pdf

0310 Operators Manual.pdf

0310 Spare Parts List.pdf

Reviews

There are no reviews yet.