Product Description

- All polypropylene construction withstands highly acidic environments

- Wide range of flow rates and surface areas for optimum bath turnover rate

- Magnetic drive pump is standard; single or double mechanical seal pumps are optional

- Available with slurry tank for easy pre-coating

- Temperatures to 190°F (90°C)

- Powder coated cover and stainless steel eyebolts and tie-down rods for superior corrosion resistance

- NEMA 4 liquid tight, corrosion resistant starter

- Large sludge holding capacity

- Specific gravities to 1.5

- Shipped ready for immediate operation

Superior Filtration of All Plating Solutions

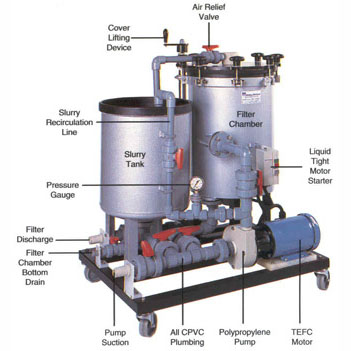

The MEFIAG ‘ALL PRO’ Series incorporates all recent advances in horizontal disc technology. A 1 HP polypropylene pump and motor provide the proper flow rate for optimum filtration of most plating solutions.

Precoating Extends Active Filter Area

‘ALL PRO’ models are available with an accessory slurry tank to simplify the addition of filter aid when precoating the filter pack. This extended active filter area prolongs filter pack life and provides enhanced particulate retention. The amount of filter aid (diatamaceous earth) is adjusted as it is added through the slurry tank, producing a uniform cake on each filter.

The Horizontal Disc Advantage

For over 30 years, MEFIAG filters have maintained their prominence in the field by consistently providing reliable, cost-effective filtration of almost every process solution used by the electroplating industry. The original disc design was so efficient that very little has been modified in the basic concept over the years.

The `ALL PRO’ Series also provides carbon treatment of organics through disposable carbon impregnated paper or conventional precoating with powdered carbon. A conversion option allows the use of granular carbon when desired.

Filter Pack Easily Maintained

All filter discs are attached to the `ALL PRO’ Series filter cover to allow easy removal for maintenance. The unique cover design on all models converts into a filter pack stand when the pack is removed. Both disposable and reusable filter media can be utilized.

MEFIAG horizontal disc filters materially reduce the plater’s disposal costs for spent media because of their efficient design. Media volume on a square foot basis is only a fraction of that experienced with cartridge type filters. Reusable and disposable cloths, felt and paper are available in a variety of retention values from 1 to 50 microns. Custom media can be formulated on request.