Description

Product Features and Benefits:

SUPERIOR CHEMICAL RESISTANCE: Materials available for use in most aqueous plating solutions.

- Fluoropolymer (PFA) models are inert to most aqueous acid, alkaline, anodizing and pickling solutions up to 212°F (100°C).

- Stainless steel and Titanium models are suitable for less corrosive applications.

- Check solution recommendation chart or with your chemical supplier for proper sheath material selectionRUGGED CONSTRUCTION: 316 stainless steel, Titanium, or fluoropolymer (PFA) covered. Heavy wall fluoropolymer (PFA) covered stainless steel element reduces permeation and eliminates the need for gas purge systems. Guaranteed 100% pinhole free.

OUTSTANDING PERFORMANCE: Low watt density design (20 watts/square inch, 3 w/cm2) for long service life. Auto stabilizing solid state element prevents hot spots and ensures uniform heating.

CORROSION RESISTANT HEAD:

- Vapor tight, flame retardant polypropylene terminal enclosure.

- 4-foot (1.2m) cord with rubber cap standard on single element 100 watt units.

- 3-foot (.9m) flexible PVC liquid tight conduit for 300 watt and larger multi-tube units.

- Plug included with 100 watt, 120-volt heater only.SAFETY FEATURES:

- Patented self-regulating design protects against overheating. Additional thermal protection not required.

- Grounded internal metal element.

- Non-floating construction.CERTIFICATIONS: CE.

SIZES: 100 watts to 1,000 watts.

VOLTAGES: 120 or 240 volts. 208 volts available. Single phase only.

OPTIONS AVAILABLE (Contact Us):

- Special configurations and lengths.

- Threaded compression fittings for through tank wall installations (single element versions only).

- Longer wire and conduit lengths.

- Titanium sheaths.

- Prewired plug-in connectors.

- Temperature and level controls sized to match the heater.

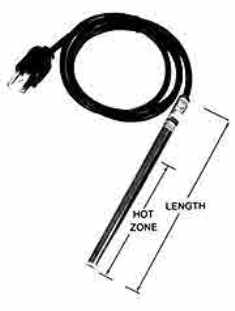

WATTS VOLTS HOT

ZONE

In./(mm)OVERALL LENGTH

In./(mm)STEEL SHIP

WGT.

Lbs./(kg)100 120

2404

(100)7

(180)VT.1107

VX.12071

(.5)300 120

2406

(155)11

(280)VT.3111

VX.32111

(.5)500 120

2406

(155)11

(280)VT.5111

VX.52111

(.5)1000 120

2406

(155)11

(280)VT1111

VX12111

(.5)Single Phase Only

Vapor tight polypropylene terminal enclosure with 4′ cord and plug (100 watt model only) and 4′ flexible PVC liquid tight conduit (on 300 through 1000 watt models). Designed for vertical installation. DO NOT immerse terminal enclosure. Optional 1/2″ PVDF screw plug adapter available for side wall mounting. Patented self-regulating design protects against overheating and fires. Plug included with 100 watt, 120VAC model only.

**THERMAL OVERLOAD PROTECTION SYSTEM: (Controller and Heater protection system must match)

Protector 1 (P1)-Standard over-temperature control system utilizes a heat sensitive fuse to detect overheat conditions. The fuse, placed inside a thermowell, positioned in contact with the heater sheath, will cut power to the heater in the event of low liquid level.

Protector 2 (P2) and Protector 3 (P3) -Optional systems provide the same reliable over temperature protection as the Protector 1; however, the control systems feature a heat sensing thermostat. Should the tank€™s liquid level drop to a preset overheat point, the thermostat will trip and an audible alarm will sound, cutting power to the heater. This eliminates dangerous operating conditions. After filling the tank, the immersion heater can be quickly made operational by pushing the reset button on the control to restore power. Protector III is designed for flexible lead or high temperature fluoropolymer (PTFE) heater applications only. DO NOT wire P3 or PT-3 devices directly to power or heater load as a dangerous short circuit will result with irreparable damage to the heater. Please refer to wiring diagrams for proper installation.

***All heaters must be operated in conjunction with appropriate temperature controls and thermal systems***

Click Here To Download:

V-SERIES DATA SHEET

**Thermal Overload Protection

Reviews

There are no reviews yet.