Product Description

The Problem…

” steady loss of precious metals through rinsewaters, strip solutions, spent plating baths and surprisingly, ion-exchange resin colums”

“lack of accountability, both in house and with outside refiners”

“the cumbersome techniques of converting recovered precious metals back to productive and/or liquid assets”

” presence of heavy metals in waste streams”

“romoving dissolved metals from stagnant solutions”

The Solution…

The most efficient and cost effective electrolytic recovery system ever

The Gold Bug® is able to bring relatively large volumes of solution with concentrations of metals all over the spectrum to environmental compliance levels in many cases. This is done quickly and inexpensively.

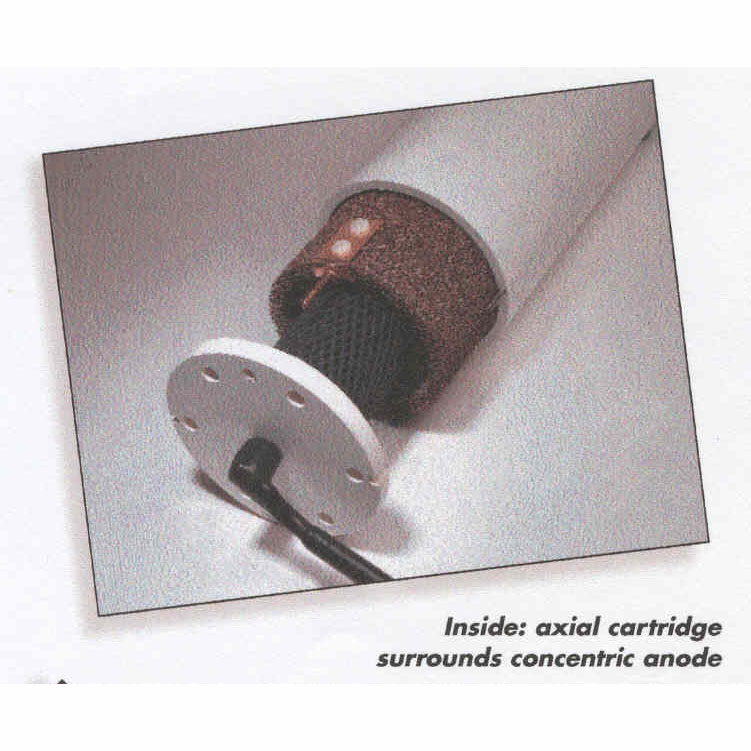

How does the Gold Bug® achieve its remarkable efficiency? The Gold Bug® employs a metallic matrix of enormous surface area which is formed into a cylindrical cathode. This, combined with the turbulence created by a dedicated pumping system, exposes the cathode to a continuously renewed concentration of fresh ions. This means fast plate-out to very low concentrations.

How does the Gold Bug® make accountability of precious metals easy? By weighing, sampling or melting the cathode, in house, The Gold Bug® allows you to know exactly what has been recovered even before the refiner knows it. Since the cathodes are inexpensive and disposable, precise record keeping and metal extraction is easy.

How can the Gold Bug® reduce my solution processing costs? You’re taking the metals out in your own shop. The water stays in your plant. Hence, no drums of solution requiring hazmat documentation, no transportation costs for heavy drums, no insurance etc. Easy, inexpensive processing with full accountability. You’re back in control.

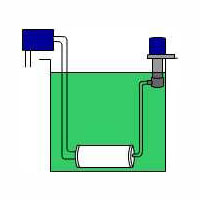

Do I need much space for the Gold Bug®? NO! The recovery cell is designed to fit within the tank holding the metal-bearing solution. Less than 1 square foot of area is all that is necessary to accommodate the Gold Bug®.

Once I remove the cathode, how do I convert this into a productive asset? After the cathode is removed and either weighed, sampled or melted, you can ship it to your refiner via registered mail. Typical refining charges are a fraction of what they would be relative to solutions or resins.

What are some of the typical applications? By far the most popular application is for point source recovery from drag-out tanks, plating baths and stripper solutions. Other applications include ion exchange regeneration, dummying, and enhancement of existing ion-exchange systems.

Can I use the Gold Bug® to dummy any of my baths? YES. When placed in a nickel bath at low voltage, the Gold Bug® is able to keep the copper concentration from ever building up to objectionable levels. It is particularly helpful because dummying can be achieved at the same time the plating is taking place. Therefore, it is no longer necessary to wait until after-hours for maintenance. The same Gold Bug® system can be moved around to many different baths.

How is the concentration of cyanide affected by using the Gold Bug®. Electrolytic dissociation of cyanide is a well-documented phenomenon. The Gold Bug® will continuously destroy free cycinide as it recovers metals, making total waste treatment that much easier.

OPERATING INFORMATION:

- Power Requirements: 110, 220 Volts AC

- Maximum Output Current: 25 Amps DC

- Optimum Output Voltage: 2.5 – 4.0 Volts, 6.0 Volts Max

- Dimensions of Collection Canister 16″ long, 5 1/2″ O.D.

- Total Cathode Surface Area: Approx. 10 square feet

- Recovery Capacity: Gold > 100 Tryo oz or 3 kilos

- Shipping Weight: 37 lbs